Digital Ceramic Print On Glass

Digital Ceramic Print On Glass is a technology that applies ceramic ink directly onto glass in much the same way that an inkjet printer prints onto paper. This solution allows the designer to create multi-color or photographic images for either monolithic or laminated installations.

Digital ceramic inks are scientifically developed with expert processes. These unique inks are fused into the glass to ensure lasting vibrancy and photorealistic color, enabling higher degrees of quality, design, and functional performance.

Digital Ceramic Print On Glass

The flexibility of printing designs into any kind of glass applications using new design elements and mimicking natural materials is redefining the possibilities for surface design. The designs are innovative and unique, but at the same time they fit varied surroundings and are easy to choose and enjoy.

Choose from any of the images or graphics in our inventory for your next project, or you can submit your own. Our inventory includes ready to print images for a variety of applications. These images and graphics can be customized in color, size and even with different levels of transparency.

The scratch and fade resistant properties of the ceramic inks are perfect for external applications such as public art installations, building facades and signage applications, for small scale specialty projects or large scale multi-panel developments.

Applications Include: Art Installations Include, Signage, Counter Tops, Wall Cladding, Backsplashes, Flooring Stairs, Marker Boards, Partitions, Elevator Cabs, and more!

For more information Contact Us

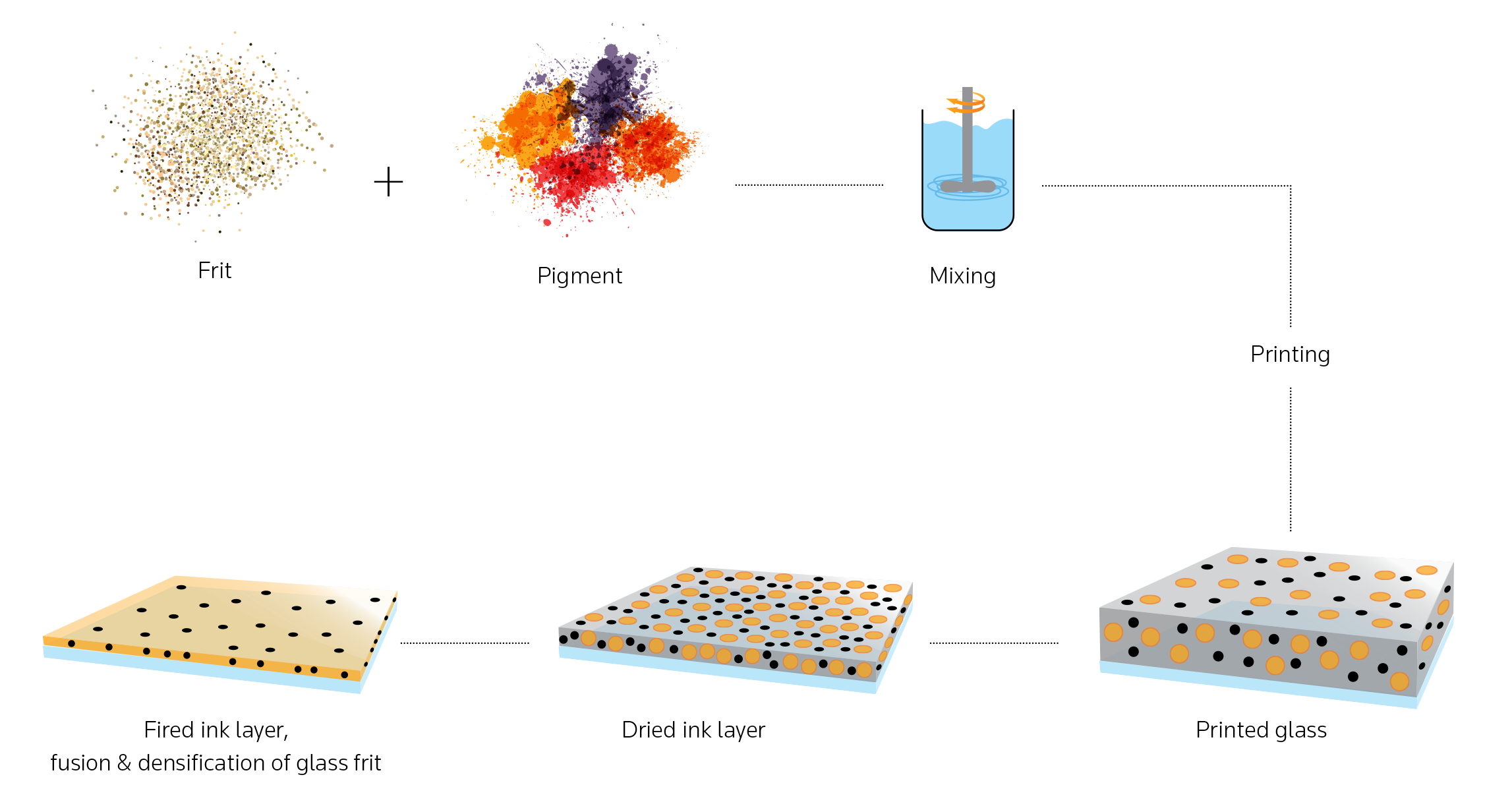

Ceramic Ink

Digital ceramic inks are scientifically developed with expert processes. These unique inks are fused into the glass to ensure lasting vibrancy and photorealistic color, enabling higher degrees of quality, design, and functional performance.

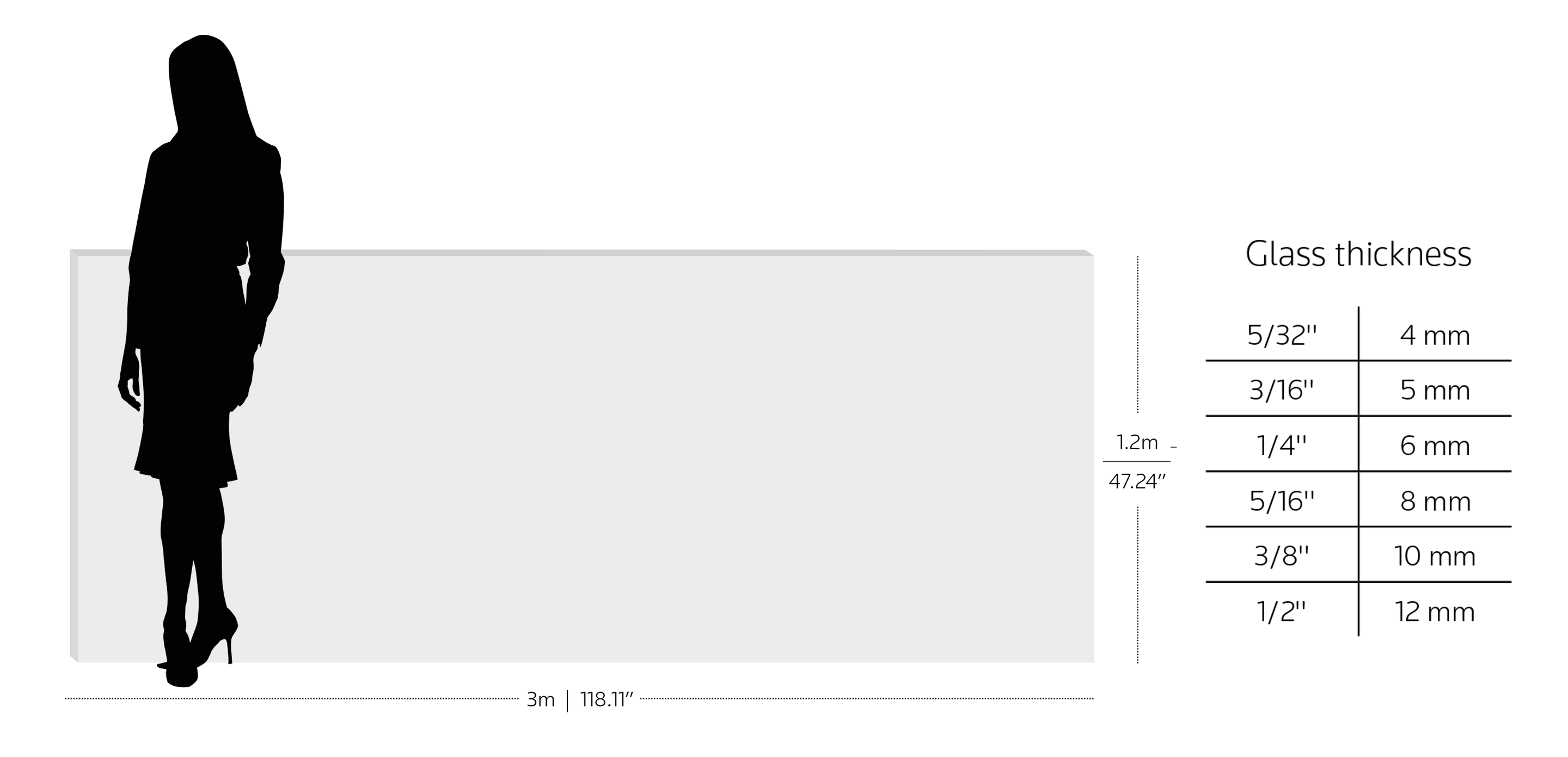

VERSATILITY IN SIZE

The advantages of digital printing are clear. Digitization and the size of the printers make it possible to print any image, in any size, however large. The printed image can be spread across many panels, to achieve any surface size and proportion. The size of one printed glass panel can reach up to 18m x 3.3m (59ft x 108ft), and multiple panels can be combined to create an image of any size.

Lamination

During the manufacturing process, but after printing, the printed glass is fixed between two glass sheets. The majority of lamination products available today have been tested and certified by Dip-Tech and the lamination manufacturers, and proven to be compliance with Dip-Tech inks. This makes the product ideal for applications requiring stronger glass to meet stringent safety parameters, such as railings, stairs, elevators, and partitions.

Glass Unit

As Dip-Tech printers can print on massive panes of glass, which are then tempered and therefore resistant to shattering, DipTech printed glass can undergo further processing for assembly into the IG unit. Although it is preferable to print on side 2, it is also possible to print on any side or layer of glass (Except for Low-E glass, as the Low-E side cannot be printed on).* * Dip-Tech has a special ink for printing on the exterior side (side 1).

Adhesion

Any adhesive approved for regular glass can be used to attach Dip-Tech glass to the wall, such as for back splashes and wall covers. Adhesion has been tested and proved for a range of wall materials, including plaster, plasterboard, brick, and cement.

Digital Ceramic Print On Glass Applications

Samples